-

Polymer oil shear stability tester (diesel nozzle method)

Shear Stability Tester for Polymer-Containing Oil (Diesel Nozzle Method) – ASTM D3945, CEC L-14-A-93 The Shear Stability Test (Diesel Nozzle Method) evaluates the viscosity loss of polymer-thickened lubricants (e.g., multigrade engine oils, hydraulic oils, and gear oils) due to mechanical shearing. This test simulates the shearing forces experienced in high-pressure fuel injection systems, gearboxes, and…

-

Fourier transform infrared spectrometer

Fourier Transform Infrared (FTIR) Spectrometer – Overview & Application in Lubricant Analysis A Fourier Transform Infrared (FTIR) Spectrometer is used for chemical composition analysis of lubricating oils, greases, fuels, and petroleum products. It identifies contaminants, degradation products, and additive depletion by analyzing how molecules absorb infrared (IR) light. 1. FTIR Applications in Lubricant & Oil…

-

Petroleum products copper strip corrosion tester

Petroleum Products Copper Strip Corrosion Tester (ASTM D130, ISO 2160, GB/T 5096) The Copper Strip Corrosion Test is used to evaluate the corrosiveness of petroleum products, such as lubricating oils, hydraulic oils, fuels, and grease, on copper components. This test determines the presence of active sulfur compounds or other corrosive elements in the sample. 1.…

-

Anti-rust grease salt spray test chamber

Salt Spray Test Chamber for Anti-Rust Grease (ASTM B117, ISO 9227) A Salt Spray Test Chamber is used to evaluate the corrosion resistance of anti-rust greases, coatings, and lubricants under controlled saline conditions. The test simulates marine and high-humidity environments to assess how well a grease protects metal surfaces. 1. Test Standards ✅ ASTM B117…

-

Engine oil apparent viscosity tester

The Engine Oil Apparent Viscosity Tester is used to measure the low-temperature and high-shear (HTHS) viscosity of engine oil, ensuring it meets cold-start and lubrication performance requirements. Depending on the test standard, different instruments are used. 1. Common Test Standards for Apparent Viscosity 1.1 Cold Cranking Simulator (CCS) – ASTM D5293 / GB/T 6538 1.2…

-

Circulating low temperature constant temperature bath

Low-Temperature Circulating Constant Temperature Bath The circulating low temperature constant temperature bath is an experimental device for precise temperature control. It is widely used in low temperature performance tests of fluids such as lubricating oil, hydraulic oil, fuel, coolant, and viscosity measurement experiments. Equipment composition Component Function Cooling system (compressor + refrigerant) Provide low temperature…

-

Marine oil-water separation tester

A Marine Oil-Water Separation Tester is a device used to test the efficiency of oil-water separators aboard ships, especially as required under MARPOL regulations (specifically Annex I, for prevention of pollution by oil). ⚓ What It Is: It is a lab or portable device that simulates how a ship’s oil-water separator (OWS) performs. The tester…

-

Hydraulic oil thermal stability tester

The thermal stability of hydraulic oil is usually determined by thermal oxidation test or oxidation stability test. The following are commonly used measurement methods and equipment recommendations: Test items Recommended equipment Purpose Hydraulic oil thermal stability test (ASTM D2070) Hydraulic oil thermal stability tester Test the oxidation stability of hydraulic oil at high temperature Rotating…

-

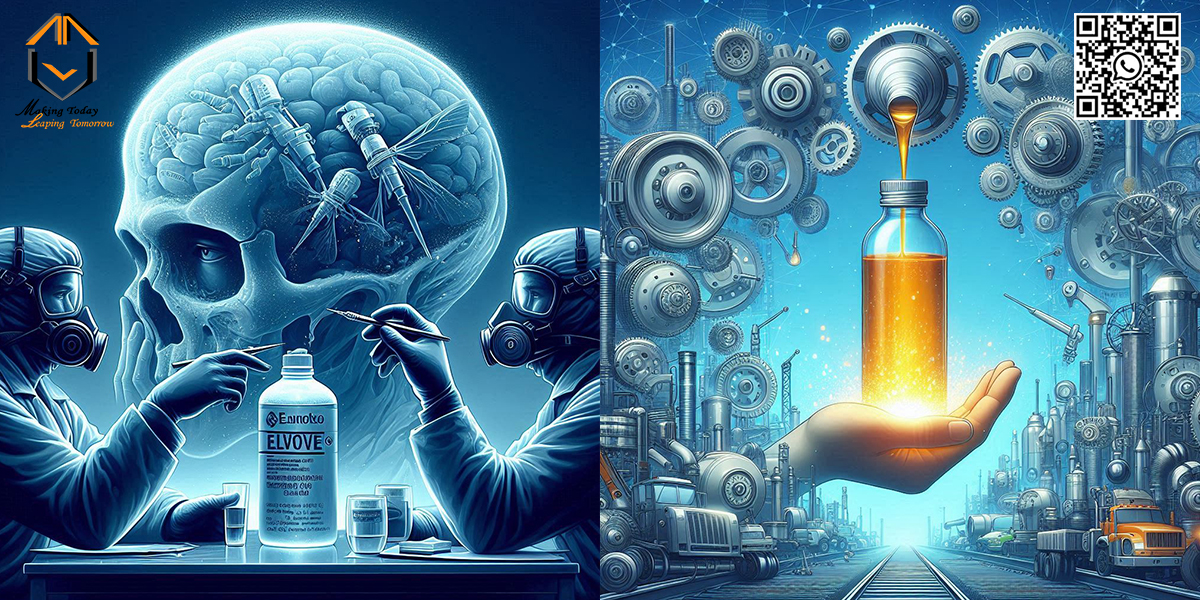

So many products can get from used lubricant ?

Yes! Used lubricants can be processed into various products, depending on the refining method and additive formulations. Here are some of the main products that can be obtained from used lubricants: 1. Re-refined Base Oil 2. Hydraulic & Transmission Oils 3. Fuel Oils & Heating Oils 4. Asphalt Extender & Bitumen Modifier 5. Lubricant Greases…

-

Can hydraulic oil and transmission oil be obtained by adding additives to waste oil after treatment?

Waste oil can indeed be regenerated into hydraulic oil and transmission oil after proper treatment and additive preparation, but it needs to undergo strict process control and quality testing to ensure that its performance meets the requirements. The general process is as follows: Refining and purification: use sedimentation, centrifugation, filtration, vacuum distillation, solvent extraction or…