-

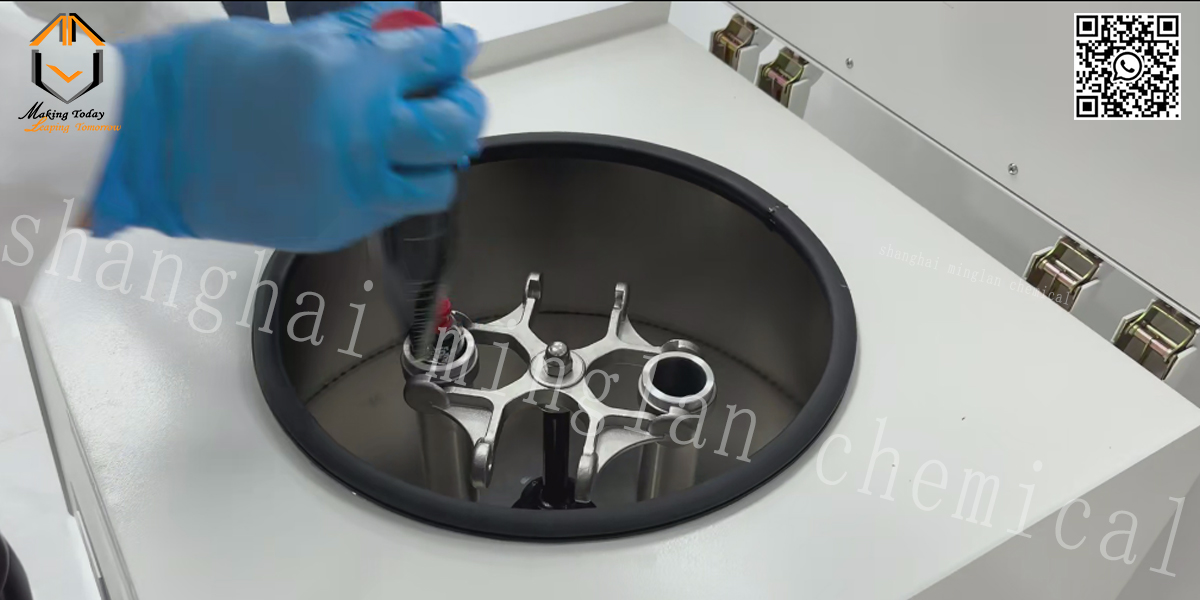

Determination of extreme pressure properties of lubricating grease (four-ball machine method)

Determination of Extreme Pressure (EP) Properties of Lubricating Grease Using the Four-Ball Machine Method The Four-Ball Machine Method is used to evaluate the extreme pressure (EP) properties of lubricating greases under high-load conditions. It determines the ability of a grease to withstand extreme pressure and prevent metal-to-metal contact. 1️⃣ Relevant Test Standards Test Method Standard Read more

-

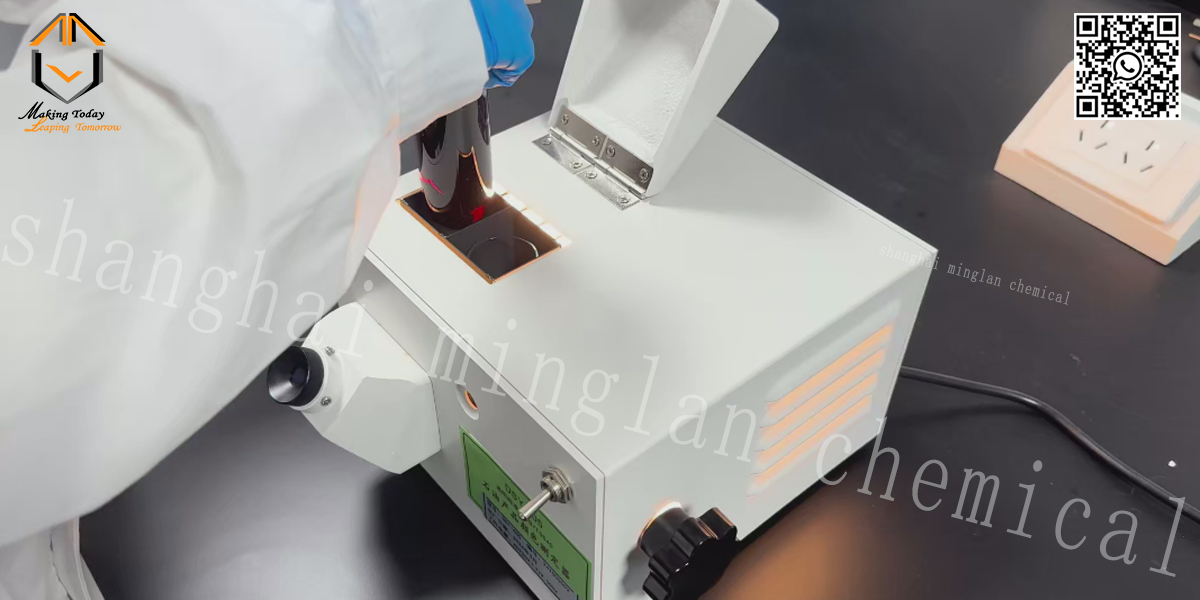

Standard test method for turbidity of lubricating oil metallic detergents

Standard Test Method for Turbidity of Lubricating Oil Metallic Detergents Turbidity measurement in lubricating oil metallic detergents helps assess dispersion quality, cleanliness, and stability of detergent additives in engine oils. 1️⃣ Relevant Test Standards Test Method Standard Application Turbidity of Lubricating Oil Detergents ASTM D6181 Measures haze/turbidity in metallic detergent additives Turbidity (ISO Method) ISO Read more

-

Pentane insoluble matter tester

A Pentane Insoluble Matter Tester is a specialized piece of laboratory equipment used primarily in the petroleum, lubricant, and additive industries to determine the amount of material in a sample that does not dissolve in n-pentane. This test is often part of quality control procedures, especially for testing lubricating oil additives, where pentane insolubles can Read more

-

Determination of sedimentation value of lubricating oil

Determination of Sediment in Lubricating Oils Sediment in lubricating oils consists of insoluble particles, contaminants, oxidation by-products, and wear debris. It is crucial to determine sediment content to evaluate the oil’s cleanliness, filtration performance, and degradation level. 1️⃣ Recommended Test Methods for Sediment in Lubricating Oils Test Method Standard Best for Sediment Detection Limit Total Read more

-

Petroleum products-Deter mlnatlon of colour

Determination of Color in Petroleum Products The color of petroleum products is an important quality indicator, as it can provide insight into refining consistency, contamination, and aging. 1️⃣ Test Standards for Color Determination ✔ ASTM D1500 – Standard Test Method for Petroleum Products by the ASTM Color Scale✔ ISO 2049 – Determination of Color of Read more

-

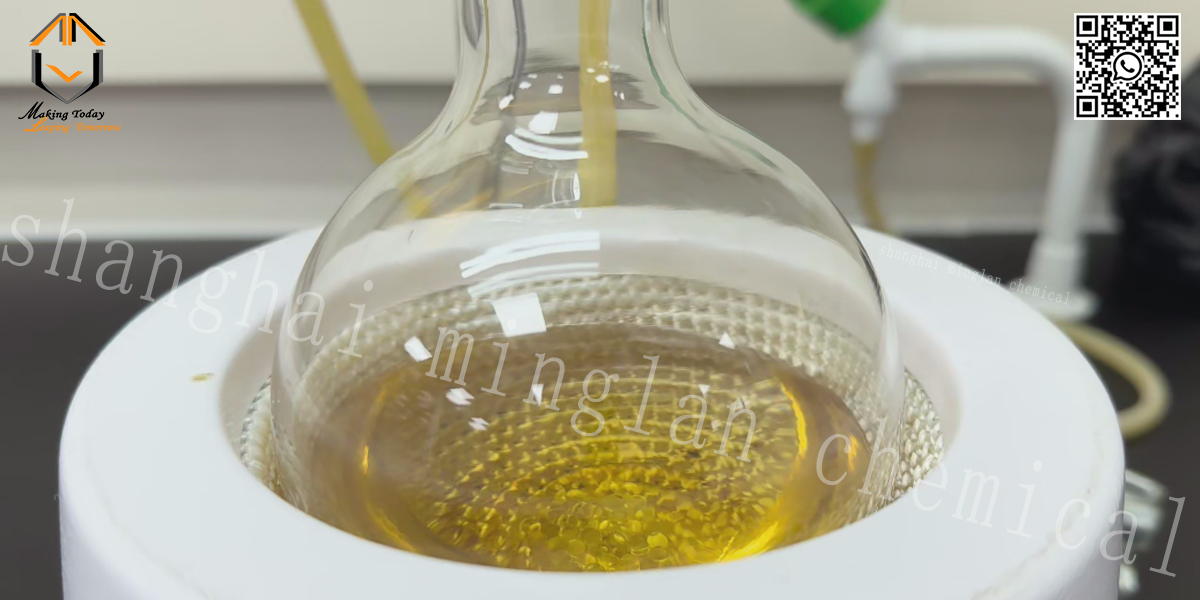

Test method for water in petroleum products—Distillation method

Test Method for Water in Petroleum Products – Distillation Method (ASTM D95 / ISO 3733) The Distillation Method is a widely used technique to determine water content in petroleum products, lubricants, and bituminous materials. This method is ideal for samples with water content ranging from 0.02% to 25%. 1️⃣ Test Standard ✔ ASTM D95 – Read more

-

Lubricants: Types, Applications, and Testing

Lubricants are essential for reducing friction, minimizing wear, and enhancing efficiency in machinery, engines, and industrial systems. They come in various forms, including oils, greases, and synthetic fluids, each designed for specific applications. 1️⃣ Types of Lubricants 1. Lubricating Oils ✅ Mineral Oil – Derived from petroleum, used in automotive and industrial applications✅ Synthetic Oil Read more

-

Inductively Coupled Plasma Optical Emission Spectrometer

Inductively Coupled Plasma Optical Emission Spectrometer (ICP-OES) An Inductively Coupled Plasma Optical Emission Spectrometer (ICP-OES) is a powerful analytical instrument used for elemental analysis in lubricants, fuels, and petroleum products. It detects and quantifies metals and trace elements at very low concentrations, making it essential for quality control, contamination analysis, and additive formulation. 1️⃣ Key Read more

-

Constant temperature water bath for pouring point

A Constant Temperature Water Bath for pour point testing is a laboratory device used to precisely control temperature during the pour point determination of petroleum products, including engine oils, diesel fuels, and lubricants. 🧪 What Is a Pour Point Test? The pour point is the lowest temperature at which an oil or fuel will still Read more