-

Shear stability tester for polymer oil

Shear Stability Tester for Polymer-Containing Oils A Shear Stability Tester evaluates the viscosity stability of polymer-containing lubricants, such as multigrade engine oils, hydraulic fluids, and gear oils, when subjected to mechanical shear stress. This test determines how polymer-based lubricants resist breakdown under high-pressure conditions, which is essential for maintaining long-term viscosity performance. Test Standards ✅ Read more

-

Lubricating oil air release value tester

Lubricating Oil Air Release Value Tester A Lubricating Oil Air Release Value Tester measures the ability of lubricating oils, hydraulic fluids, and turbine oils to release entrained air. This property is critical for preventing foam formation, maintaining lubrication performance, and ensuring reliable operation in high-speed machinery. Test Standards ✅ ASTM D3427 – Standard Test Method Read more

-

Petroleum and synthetic fluid water separation tester

A Petroleum and Synthetic Fluid Water Separation Tester designed for GB/T 7305 and ASTM D1401 standards is used to evaluate the demulsibility (water separation ability) of petroleum-based and synthetic oils. Key Features of the Tester ✅ Test Standards: Complies with ASTM D1401 (Standard Test Method for Water Separability of Petroleum Oils and Synthetic Fluids) and Read more

-

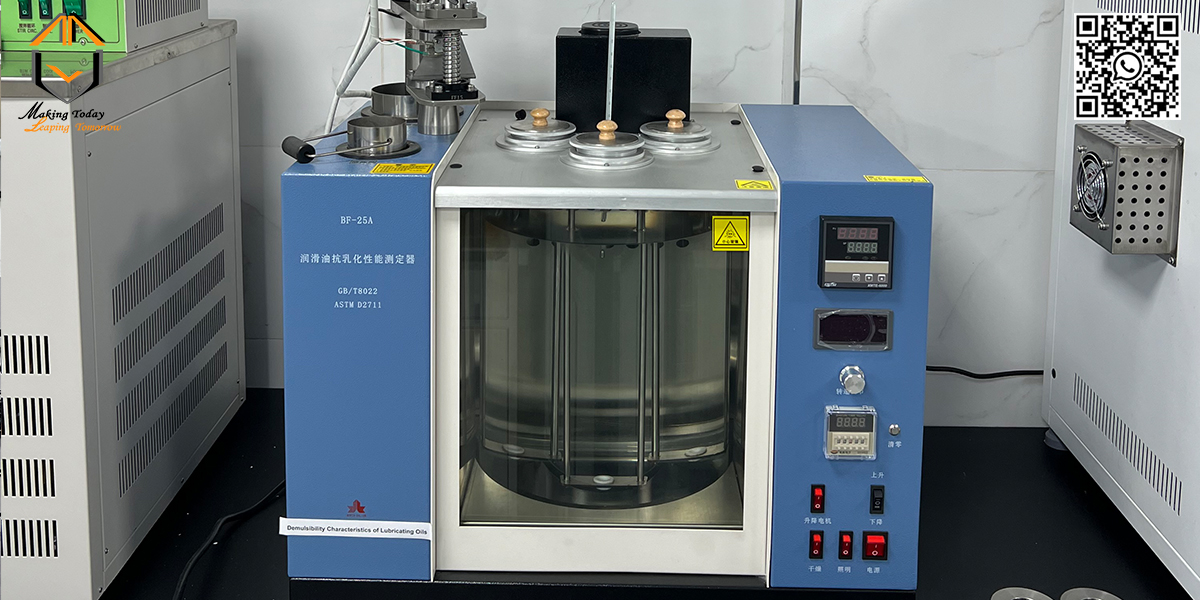

Lubricating oil demulsification performance tester

Lubricating Oil Demulsification Performance Tester (ASTM D1401 / SH/T 0301) A lubricating oil demulsification performance tester evaluates an oil’s ability to separate from water. This is crucial for turbine oils, hydraulic fluids, and gear oils, as poor demulsibility can cause emulsion formation, poor lubrication, and system failure. 1. Test Standard: ASTM D1401 / SH/T 0301 Read more

-

Lubricating oil anti-foam tester

Lubricating Oil Anti-Foam Tester – ASTM D892 The Anti-Foam Test for Lubricating Oils (ASTM D892) evaluates an oil’s ability to resist foam formation and break down foam efficiently. This test is crucial for engine oils, hydraulic fluids, gear oils, and turbine oils, as excessive foam can cause poor lubrication, cavitation, and system failure. 1. Equipment Read more

-

Lubricating oil oxidation stability tester (rotating oxygen bomb method)

Lubricating Oil Oxidation Stability Tester (Rotating Oxygen Bomb Method) – ASTM D2272 The Rotating Oxygen Bomb (ROB) Test, also known as ASTM D2272, is a widely used method to evaluate the oxidation stability of lubricating oils by measuring the time it takes for oil to react with oxygen under accelerated conditions. This test is essential Read more

-

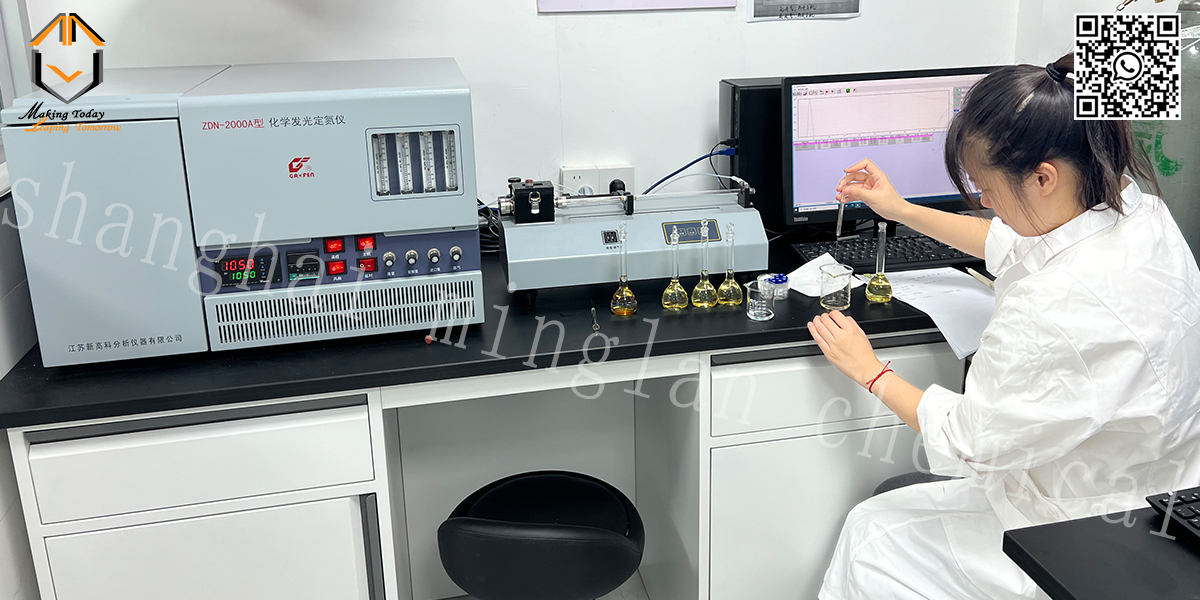

Chemiluminescence nitrogen analyzer

Chemiluminescence Nitrogen Analyzer (CLNA) – Principle & Applications A Chemiluminescence Nitrogen Analyzer (CLNA) is used to measure total nitrogen (TN) content in petroleum products, lubricants, fuels, and other organic materials. It is widely applied in quality control, fuel research, and environmental testing. 1. Key Applications ✅ Lubricants & Fuel Analysis: Determines nitrogen content in diesel, Read more

-

Block-on-Ring Wear Tester

Block-on-Ring Wear Tester (ASTM D2714, ASTM G77) A Block-on-Ring Wear Tester is used to evaluate the friction, wear resistance, and load-carrying capacity of lubricants, coatings, and materials under sliding contact conditions. It is commonly applied in lubricating oil, grease, metal coatings, and additive performance testing. 1. Key Applications ✅ Lubricant Testing: Evaluates the wear protection Read more

-

Polymer oil shear stability tester (diesel nozzle method)

Shear Stability Tester for Polymer-Containing Oil (Diesel Nozzle Method) – ASTM D3945, CEC L-14-A-93 The Shear Stability Test (Diesel Nozzle Method) evaluates the viscosity loss of polymer-thickened lubricants (e.g., multigrade engine oils, hydraulic oils, and gear oils) due to mechanical shearing. This test simulates the shearing forces experienced in high-pressure fuel injection systems, gearboxes, and Read more