-

What are some common pour point depressants used in lubricating oils?

Pour point depressants (PPDs) are additives used in lubricating oils to lower the temperature at which the oil becomes semi-solid and loses its flow characteristics. This is particularly important in cold climates, where lubricants must remain fluid to ensure proper lubrication and operation of machinery and engines. Here are some common types of pour point…

-

What are metal working fluids?

Metalworking fluids (MWFs) are specialized liquids or gels used in industrial processes involving metalworking operations such as machining, milling, drilling, grinding, and cutting. Metalworking fluids (MWFs) are a broad category of liquids and gases used in various machining and metalworking processes to improve tool life, reduce friction and heat generation, and improve surface finish. They…

-

What are the formulations of metalworking fluids?

Metalworking Fluids: Discover Their Formulations and Functions Metalworking fluids play a vital role in industrial production, and their performance directly affects the quality and efficiency of metal processing. Metalworking fluids can be divided into two categories: oil-based cutting fluids and water-based cutting fluids according to their composition. First, let’s look at oil-based cutting fluids. Oil-based…

-

What are the formulations of metalworking fluids?

Metalworking fluids (MWFs) are formulated to meet specific requirements for various metalworking processes, such as cutting, grinding, milling, and forming. These formulations typically consist of a base fluid, additives, and water (if the MWF is water-based). The exact composition of metalworking fluid formulations can vary based on factors such as the type of metal being…

-

What is the market for metalworking fluid additives?

The market for metalworking fluid additives is driven by the growing demand from various industries, including automotive, aerospace, machinery, and construction. Metalworking fluids (MWFs) are essential in these industries to improve the efficiency, quality, and lifespan of metalworking processes such as cutting, drilling, milling, and grinding. The metalworking fluid additive market mainly includes cutting fluid…

-

What is the role of additives in metalworking fluids?

Additives play a crucial role in enhancing the performance, stability, and longevity of metalworking fluids (MWFs) used in various machining and metal forming operations. These additives are designed to address specific challenges associated with metalworking processes, such as friction, heat generation, corrosion, and microbial growth. While the base fluid (often mineral oil, water, or synthetic)…

-

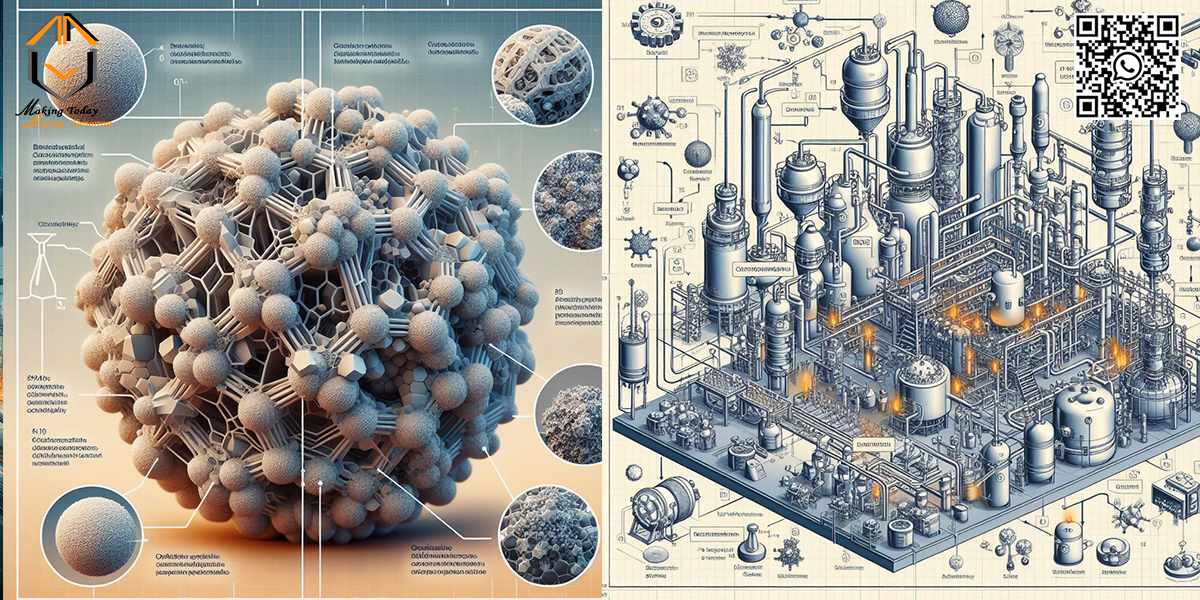

Olefin Catalytic Cracking Catalyst

Olefin catalytic cracking is a significant process in the petrochemical industry used to convert higher molecular weight olefins, such as butenes and pentenes, into lower molecular weight olefins like ethylene and propylene, which are essential building blocks for various petrochemical products, including plastics, resins, and synthetic rubbers. The cracking reaction involves the cleavage of carbon-carbon…

-

Methanol to Olefins Catalyst

The conversion of methanol to olefins (MTO) is a significant chemical process used to produce light olefins, such as ethylene and propylene, which are crucial building blocks for various petrochemical products, including plastics, resins, and synthetic rubbers. The MTO process involves the catalytic dehydration and oligomerization of methanol to form a mixture of olefins, primarily…

-

Preparation of Isopropylbenzene by Liquid-phase Radicalization of Benzene and Propylene Catalyst

The preparation of isopropylbenzene (also known as cumene) by the liquid-phase radicalization of benzene and propylene is a significant chemical process used in the petrochemical industry. Isopropylbenzene is a key intermediate in the production of phenol and acetone, which are essential raw materials for various industries, including plastics, resins, and pharmaceuticals. The process involves the…

-

Alkylation to Ethylbenzene Catalyst

Alkylation to ethylbenzene is an essential chemical process used in the petrochemical industry to produce ethylbenzene, which is a key intermediate in the production of styrene, a vital monomer for the manufacturing of polystyrene plastics and synthetic rubbers. The alkylation reaction involves the combination of benzene with ethylene or ethyl chloride in the presence of…