-

What are some examples of friction modifier selection?

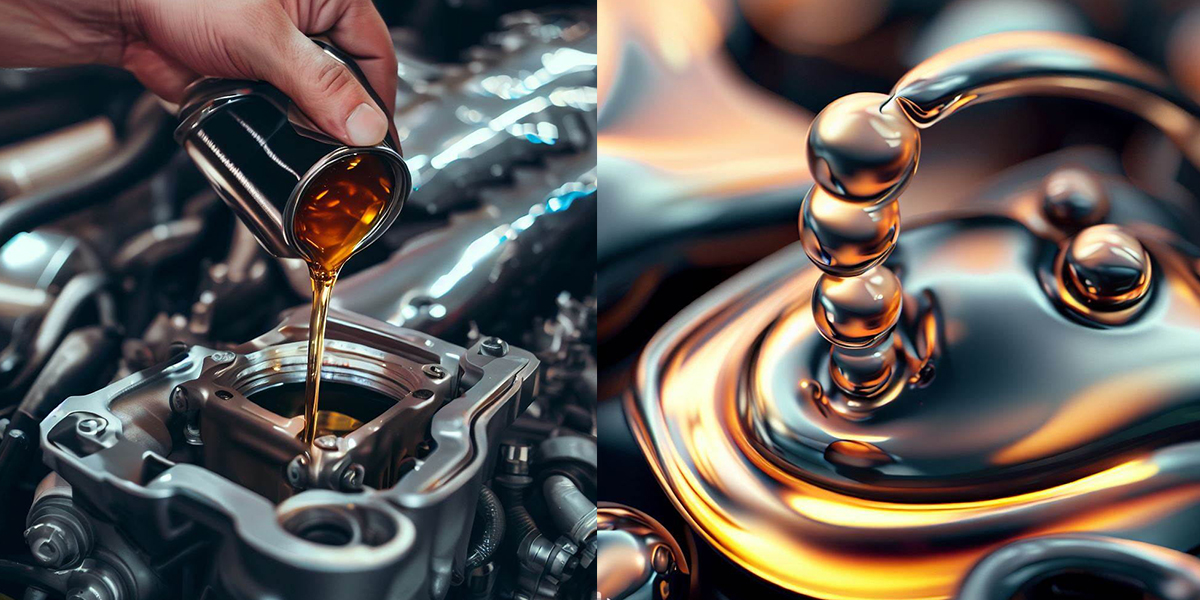

In the operation of mechanical equipment, the selection and use of lubricating oil is crucial. To ensure smooth operation of equipment and extend its service life, friction modifiers are often added to lubricating oils. Let’s understand what lubricants and friction modifiers are. Lubricating oil is a liquid medium designed to reduce friction and wear, while…

-

What is the Universal Passenger Car Engine Oil Additive Package

An engine oil additive package is a combination of various chemical compounds designed to enhance the performance and protection of engine oils. These additives are blended into the base oil to create a finished product that meets specific performance requirements for different types of engines. The term “universal passenger car engine oil additive package” suggests…

-

Determination of lubricating oil formula ingredients

Determining the specific ingredients in a lubricating oil formula typically involves a combination of laboratory analysis, formulation knowledge, and understanding of industry standards. Here’s a general overview of the process: By combining these approaches, lubricating oil formulators and analysts can effectively determine the ingredients in a lubricating oil formula, ensuring that the oil meets desired…

-

Why use BHT as an antioxidant in lubricants?

BHT (Butylated Hydroxytoluene) is widely used as an antioxidant in lubricants due to its excellent ability to prevent oxidative degradation of base oils and additives. Its chemical name is 2,6-di-tert-butyl-4-methylphenol. 🧪 Why Use BHT in Lubricants? ✅ 1. Prevents Oxidation ✅ 2. Protects Oil Longevity ✅ 3. Low Cost and Widely Available ✅ 4. Thermal…

-

What impact does the choice of extreme pressure additives have on lubricants?

The choice of extreme pressure (EP) additives has a critical impact on the performance, durability, and compatibility of lubricants — especially in gear oils, greases, and industrial applications where heavy loads, shock, and metal-to-metal contact are common. 🔧 What Are EP Additives? EP additives are chemical compounds added to lubricants to prevent wear, pitting, scuffing,…

-

Insufficient viscosity index of lubricating oil: problems, causes and solutions

Lubricating oil plays a vital role in the normal operation of mechanical equipment. Among them, viscosity index is one of the important indicators to evaluate the performance of lubricating oil. However, in actual use, sometimes the viscosity index of the lubricating oil is insufficient, which can lead to a series of problems. This article will…

-

What are the uses of lubricant additives?

Lubricating oil additives are substances added to lubricating oils and greases to enhance their performance and characteristics. These additives are blended into the base oil to provide specific functions and increase the overall effectiveness of the lubricant. Lubricating oil additives are special chemicals that are added to lubricating oil to improve its performance. They enhance…

-

What is the role of defoaming agents in lubricating oils?

Defoaming agents in lubricating oils are mainly used to prevent foam formation and accumulation. When lubricating oil is agitated or subjected to high speeds or temperatures, air can be entrained and foam can form. Foam can adversely affect lubricant performance because it can lead to insufficient lubrication, increased wear, reduced cooling efficiency, and reduced overall…

-

What is the role of selecting extreme pressure additives?

The role of extreme pressure additives in lubricants is to provide enhanced protection against extreme pressure and high load conditions. These additives are designed to form a protective film between metal surfaces, preventing direct metal-to-metal contact and reducing friction, wear and damage. Extreme pressure additives often contain compounds such as sulfur, phosphorus or chlorinated compounds…

-

Choose What is the viscosity index of a liquid?

A liquid’s viscosity index is a measure of its resistance to flow as a function of temperature. It is a quantitative measurement that indicates how much a liquid’s viscosity changes with temperature. The viscosity index provides information about the stability of a fluid’s viscosity over a range of temperatures. The viscosity of a liquid is…