-

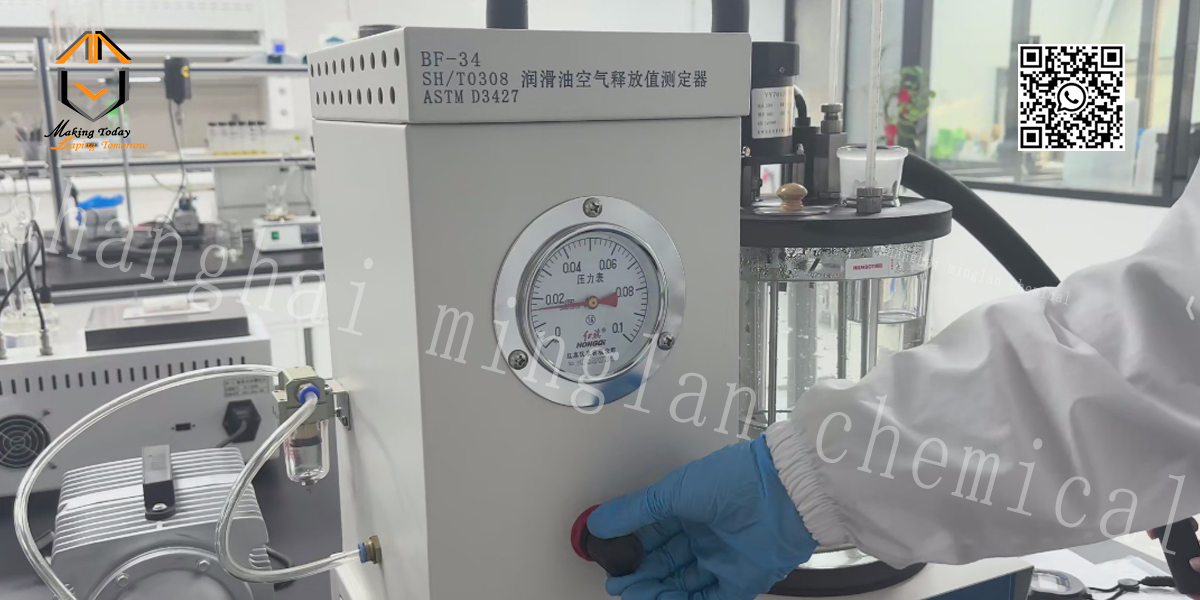

Determination of air release value of lubricating oil

Determination of Air Release Value of Lubricating Oil (ASTM D3427 / ISO 9120) 🔹 Purpose of the Test The air release value measures how quickly entrained air is released from a lubricating oil after being subjected to aeration. This property is critical for: ✅ Hydraulic oils – Prevents air bubbles that affect hydraulic performance✅ Turbine…

-

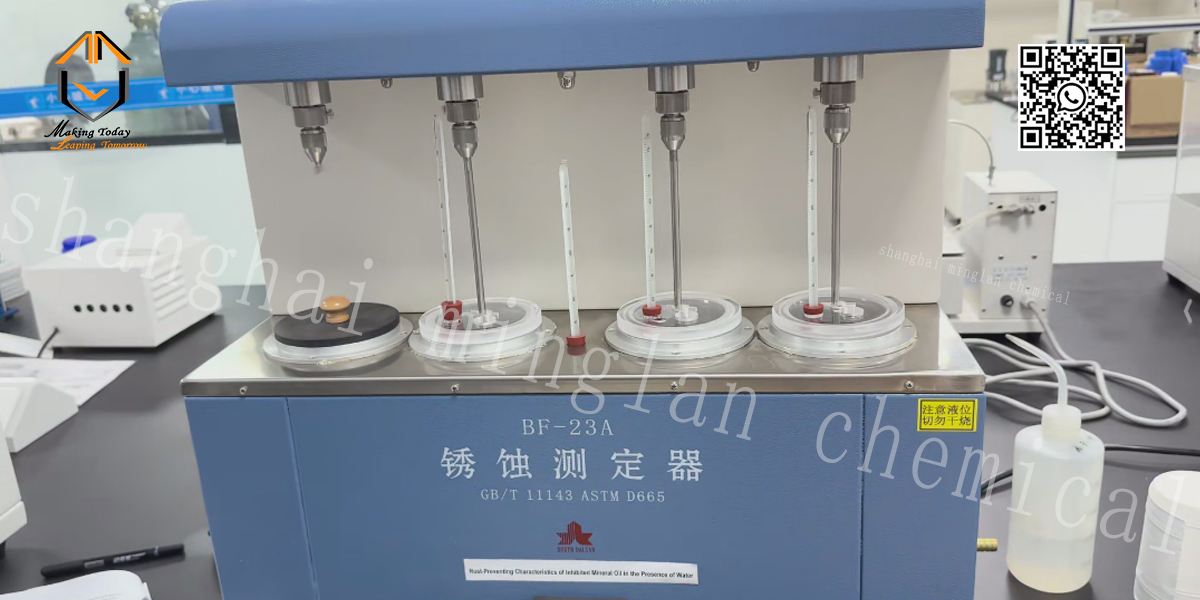

Standard test method for rust-preventing characteristics of inhibited mineral oilin the presence of water

Standard Test Method for Rust-Preventing Characteristics of Inhibited Mineral Oil in the Presence of Water (ASTM D665 / ISO 7120) 🔹 Purpose of the Test This method evaluates the rust-preventing characteristics of inhibited mineral oils, such as lubricating oils, hydraulic fluids, and turbine oils, when mixed with water. It determines whether an oil can protect…

-

Determination of base value of petroleum products (perchloric acid potentiometric titration method)

Determination of Base Number (BN) in Petroleum Products – Perchloric Acid Potentiometric Titration Method (ASTM D2896) The Base Number (BN) of a petroleum product measures its ability to neutralize acidic contaminants that form during combustion and oxidation. The Perchloric Acid Potentiometric Titration Method (ASTM D2896) is a precise technique for determining BN in lubricants, engine…

-

Lever type four-ball friction testing machine

A lever-type four-ball friction testing machine is a specialized tribological test device used to measure the anti-wear, extreme pressure (EP), and friction-reducing performance of lubricants, greases, and additives under high-load conditions. It operates based on the Four-Ball Wear Test principle, but with a lever arm mechanism for applying load. ⚙️ Basic Principle: 🧪 Key Test…

-

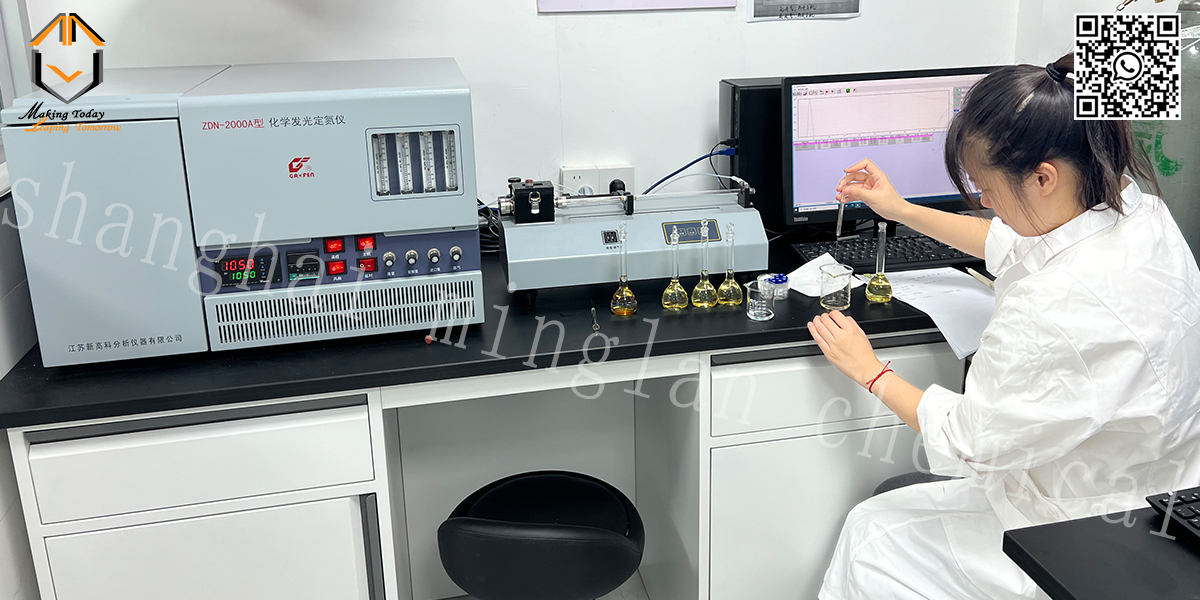

Chemiluminescence nitrogen analyzer

Chemiluminescence Nitrogen Analyzer (CLNA) – Principle & Applications A Chemiluminescence Nitrogen Analyzer (CLNA) is used to measure total nitrogen (TN) content in petroleum products, lubricants, fuels, and other organic materials. It is widely applied in quality control, fuel research, and environmental testing. 1. Key Applications ✅ Lubricants & Fuel Analysis: Determines nitrogen content in diesel,…

-

Kinematic viscosity tester

Kinematic Viscosity Tester(Kinematic Viscosity Tester) Kinematic viscosity is a key indicator for evaluating the fluidity of lubricating oil, hydraulic oil, diesel, fuel oil, etc., usually measured in mm²/s (cSt). Common test standards include ASTM D445, ISO 3104, and GB/T 265. Composition of Kinematic Viscosity Tester Main equipment: Device Name Application Kinematic Viscosity Tester Maintain constant…

-

Method of Work and Quantities for Lubricating Oils and Greases Production

Below is a detailed breakdown of the method of work and approximate quantities required to produce lubricating oil and grease in a simple production setup. 1. Production of Lubricating Oil Method of Work (Step-by-Step Process) Step 1: Base Oil Preparation Step 2: Additive Blending Step 3: Homogenization & Filtration Step 4: Quality Testing Step 5:…

-

Manufacturing Process for Oils and Greases: A Simple Production Line

The production of oils and greases involves several key steps to ensure the final product meets the required specifications for lubrication, protection, and performance. Below is an overview of the simple production line for both oils and greases: 1. Manufacturing of Oils (Lubricants) Ingredients Used: Production Process: 2. Manufacturing of Greases Ingredients Used: Production Process:…

-

Are there any special considerations when using sodium petroleum sulfonate in high temperature industrial applications?

When using Sodium Petroleum Sulfonate in high-temperature industrial applications, several special considerations should be taken into account to ensure optimal performance and stability: 1. Thermal Stability: 2. Oxidation Resistance: 3. Compatibility with Base Oils: 4. Shear Stability: 5. Evaporation and Volatility: 6. pH Sensitivity: 7. Environmental and Regulatory Considerations: Recommendations: By considering these factors, you…