-

Can hydraulic oil and transmission oil be obtained by adding additives to waste oil after treatment?

Waste oil can indeed be regenerated into hydraulic oil and transmission oil after proper treatment and additive preparation, but it needs to undergo strict process control and quality testing to ensure that its performance meets the requirements. The general process is as follows: Refining and purification: use sedimentation, centrifugation, filtration, vacuum distillation, solvent extraction or Read more

-

Should EVA be dissolved in xylene to prepare the solution? If so, what ratio and operational conditions are recommended?

Yes, xylene is a commonly used solvent to dissolve Ethylene Vinyl Acetate (EVA) when preparing solutions for use in lubricant formulations or as a pour point depressant (PPD). Xylene is a good choice because it is a hydrophobic solvent that can dissolve a variety of non-polar and semi-polar polymers like EVA while offering the necessary Read more

-

Learn about the production of pour point depressants (PPDs) from ethylene vinyl acetate (EVA).

Producing Pour Point Depressants (PPDs) using Ethylene Vinyl Acetate (EVA) is an interesting and valuable approach in the field of lubricants, especially for improving the cold-flow properties of oils. Let’s break down how EVA-based PPDs are produced and how they function in cold weather conditions. Understanding the Role of Pour Point Depressants (PPDs): PPDs are Read more

-

How can boric acid be dissolved in oil or lubricant, and at what percentage should it be mixed?

Boric acid is not naturally oil-soluble, so to dissolve it in oil or lubricant, you need to use a chemical modification or dispersion method. Here are some approaches: Methods to Dissolve Boric Acid in Oil: Recommended Concentration in Lubricants The optimal percentage depends on the lubricant type and desired performance characteristics. Higher concentrations may require Read more

-

waste engine oil add to some powder this powder will heat the waste engine oil

Yes, some powdered substances can be used to heat and treat waste oil to help remove impurities, reduce viscosity, and improve performance. Here are some common additives and heating methods: 📌 1. How powder heating waste oil worksWhen certain powders (such as quicklime) react with water, they release heat, which increases the temperature of the Read more

-

Waste oil is processed into grease through filtration treatment

Methods of processing waste oil into grease after filtration treatmentUsing waste oil to produce grease is an economically viable method, but it requires proper treatment and additives to ensure that the performance of the grease meets the requirements. The following is a simple production process without vacuum distillation or oil regeneration equipment. Carefully extract the Read more

-

can produce grease from waste engine oil ??

Yes, it is possible to produce grease from waste engine oil, and this is actually done in small-scale or rural industrial settings where used oil is recycled into low-cost lubricating grease. However, it requires the right chemicals, processing steps, and safety precautions. ✅ Basic Overview: How to Make Grease from Waste Engine Oil 🧪 Main Read more

-

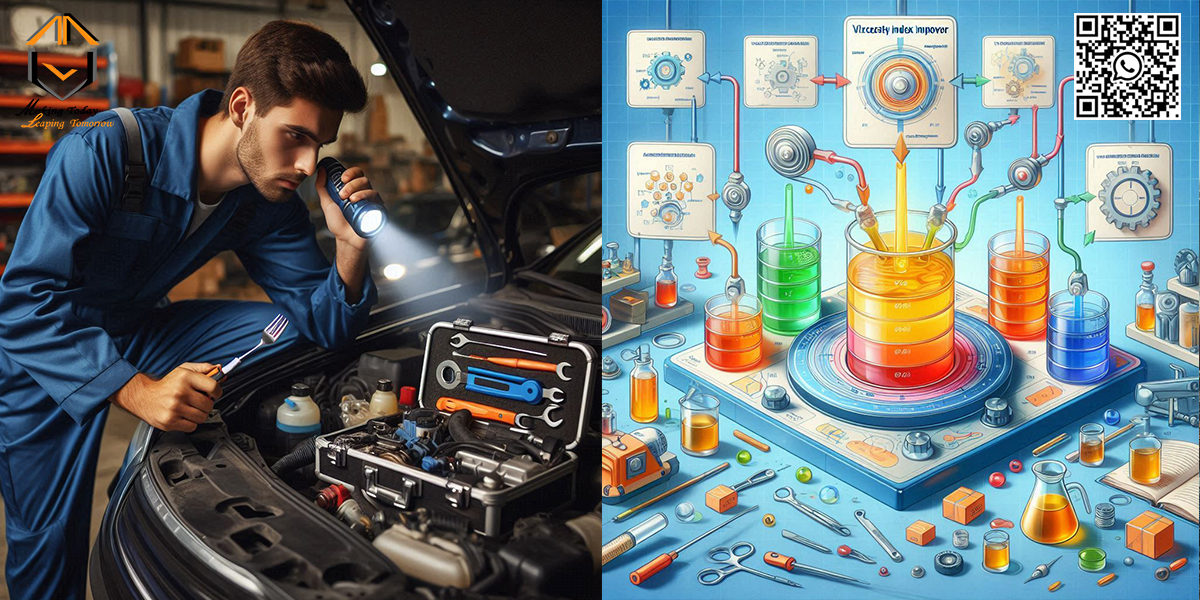

How Viscosity Index Improver Works (Visualized)

How Viscosity Index Improvers (VIIs) Work: A Visualized Explanation Viscosity Index Improvers (VIIs) are key additives in engine oils that help to maintain an optimal oil viscosity across a wide range of temperatures. The viscosity of an oil refers to its resistance to flow, and it’s important to have a stable viscosity for effective lubrication Read more

-

1 ton of T66330 CI-4/SL Engine Oil Additive Package can be used for how many tons of filtered oil?

T66330 CI-4/SL Engine Oil Additive Package is typically used at a recommended treat rate of 10% – 12% by weight when blending with base oil to formulate finished engine oil. Calculation for 1 Ton of T66330 Additive Package Final Answer: Depending on the required treat rate (10%-12%), 1 ton of T66330 additive package can produce Read more