-

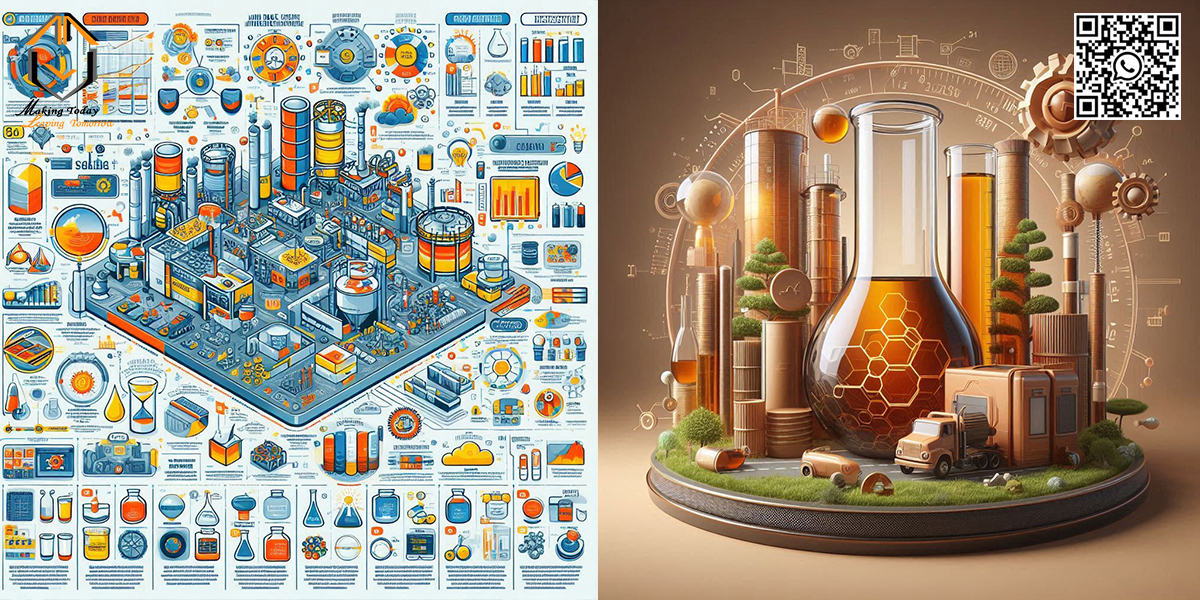

Method of Work and Quantities for Lubricating Oils and Greases Production

Below is a detailed breakdown of the method of work and approximate quantities required to produce lubricating oil and grease in a simple production setup. 1. Production of Lubricating Oil Method of Work (Step-by-Step Process) Step 1: Base Oil Preparation Step 2: Additive Blending Step 3: Homogenization & Filtration Step 4: Quality Testing Step 5: Read more

-

Production Method and Raw Materials for Lubricating Oils and Greases

1. Production of Lubricating Oil (Engine Oil, Gear Oil, Hydraulic Oil, etc.) Raw Materials: Production Method: 2. Production of Grease Raw Materials: Production Method: 3. Simple Production Line Setup Basic Equipment Needed: The production of lubricating oils and greases follows a structured process that involves base oil selection, additive blending, homogenization, quality testing, and packaging. Read more

-

Manufacturing Process for Oils and Greases: A Simple Production Line

The production of oils and greases involves several key steps to ensure the final product meets the required specifications for lubrication, protection, and performance. Below is an overview of the simple production line for both oils and greases: 1. Manufacturing of Oils (Lubricants) Ingredients Used: Production Process: 2. Manufacturing of Greases Ingredients Used: Production Process: Read more

-

Detergent and dispersant action

Detergent and Dispersant Action in Engine Oils Engine oils contain a blend of additives that perform critical roles in protecting engines and ensuring optimal performance. Among these, detergents and dispersants are essential in maintaining cleanliness and preventing harmful deposits. Detergent Action Detergents are chemical additives designed to: Key Features of Detergents: Dispersant Action Dispersants are Read more

-

Explain what base number is and why it matters in engine oil

What Is Base Number (BN)? The Base Number (BN) of an engine oil is a measure of its ability to neutralize acids that are produced during the combustion process, particularly in engines using sulfur-rich fuels. It is expressed in milligrams of potassium hydroxide (KOH) per gram of oil, indicating how much base (alkaline substance) is Read more

-

High Base Number Additives: Applications

High Base Number Additives: Applications High Base Number (High-BN) additives are essential components in lubricants designed for demanding applications where high levels of acid neutralization, cleaning, and performance under harsh conditions are required. Their applications span industries such as automotive, marine, industrial, and power generation. 1. What Are High Base Number Additives? The Base Number Read more

-

Tar in Grease

Causes and Solutions for Tar in Grease During the use or storage of grease, tar-like substances are sometimes produced. This phenomenon is usually caused by thermal decomposition, oxidation, contamination or chemical instability of the grease. The following are the main reasons for the production of tar and the corresponding solutions: High-temperature decomposition When grease is Read more

-

About component required for making spin finish oil

Spin finish oil is a specialized formulation used in the textile industry, primarily for synthetic fiber production, such as polyester, nylon, or polypropylene. It is applied to fibers during their production process to impart specific properties like lubrication, antistatic behavior, cohesion, and smooth processing. Key Components of Spin Finish Oil Formulation Considerations Testing and Optimization Read more

-

Can soluble polymers be used to reduce the pour point of paraffin wax?

Yes, soluble polymers can be used to reduce the pour point of paraffin wax, mainly by changing the formation and aggregation of wax crystals in paraffin wax, thereby improving low-temperature fluidity. The following is a detailed analysis and suggestions: Crystal modification: polymers adsorb on the surface of wax crystals to change their crystal morphology, making Read more